Energy models are notorious for requiring lots of detail. But just how much detail is required, and can that be quantified? In this post we’ll try to do that, and figure out just how many numbers go into an energy model.

PDF version here

Complexity: Intermediate

Warning: this post uses BEDMAS (cheers from the engineers!)

Shakespeare famously asked “what’s in a name”?”

Today we’re going to look at what’s in an energy model. And really, what is there but a collection of numbers? Lots and lots of numbers. But how many? Today we’re going to find out. And if you’re not a numbers person, bear with us as there’s good news for you at the end.

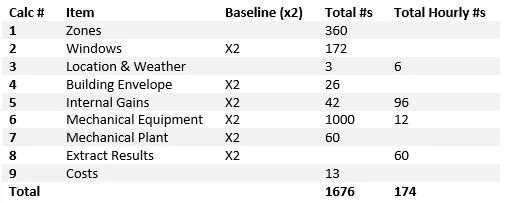

Let’s do a rough calculation on a generic project, a 4-story, wood-frame townhouse project with 100 suites, located in Victoria BC. We’re going to model this project to comply with the BC Building Code, using the ASHRAE 90.1-2010 Energy Cost Budget (ECB) method.

We’ll start with geometry, which may be the hardest part to quantify. Our 100-suite building has 25 suites per floor; let’s add 5 common spaces for a round 30 zones per floor. Assuming each zone is a rectangular box; to draw this correctly we need 3 dimensions: length, width and height. Yay our first calculation!

Calculation 1: Zones = 30 per floor x 4 floors x 3 dimensions = 360 numbers

Ok now we’re going to add windows. Let’s assume that there are windows on each exterior wall of each suite (never mind the common spaces). On each floor we’ll have 4 corner units with 2 exterior walls, and the rest will have 1 exterior wall. For the windows we also need 3 dimensions: length, width, and sill height.

Calculation 2: Windows = (21 x 1 + 4 x 2) per floor x 3 floors = 87 numbers

Now we need to place our model in Victoria. We’re going to lump a bunch of numbers together here so stay with me. Latitude, Longitude and elevation are pretty straightforward (we’ll keep the building above sea level, at least for now until climate change gets the better of us… oops off topic!) For now, let’s focus on these variables: exterior dry bulb temperature, exterior wet bulb temperature, wind speed, direct solar, diffuse solar and cloud cover. But the weather file contains 8760 numbers (for each hour of the year) for each variable*. For now we’re going to keep track of these separately.

*I hear some of you saying “but your weather files are already prepared for you, so it’s not much work”. That can be true for buildings using “standard weather year” files, but sometimes the modeller has to adjust a file to calibrate it to local conditions, or perhaps to an actual weather year for an existing building analysis.

Calculation 3a: Location = 3 inputs = 3 numbers

Calculation 3b: Weather = 6 variables = 6 hourly numbers

Next we need to apply the building envelope to the geometry. Let’s assume a standard roof, 5 types of above- and below-grade walls, a balcony slab edge, two types of floors and two types of glazing. All need U-values (or R-values) and the glazing needs a Solar Heat Gain Coefficient (SHGC).

Calculation 4: Building Envelope = 11 U-values + 2 SHGC = 13 numbers

Now we get to our internal gains- looking at what’s going on inside the building. We’ll focus on occupancy, plug loads, appliances and lighting. Let’s assume that these are the same across a “type” of zones- so all suites have the same number of people, lighting wattage, etc. Aside from our suites we also have corridors, stairs, elevators, elevator lobbies, an entry lobby, storage rooms and vestibules. So that’s 8 types of rooms and 3 variables plus schedules. For simplicity, we’ll assume the same schedule for each weekday and weekend, each with 24 hourly inputs.

Calculation 5a: Internal Gains = 3 variables x 7 rooms = 21 numbers

Calculation 5b: Internal Gains = 8 room types x 3 variables x 2 schedules = 48 hourly numbers

Onto our mechanical systems. For each room we have to account for 5 variables: heating load, heating setpoint, cooling load, cooling setpoint and ventilation. Each entry will have a value (for example: ventilation will be the outdoor air rate) and schedules; again we’ll assume that a standard 24-hour weekday and 24-hour weekend schedule can be used for each of the 8 room types.

Calculation 6a: Mechanical Systems = 100 rooms x 5 variables = 500 numbers

Calculation 6b: 3 Mechanical Systems = 3 variables x 2 schedules = 6 hourly numbers

Next let’s look at our mechanical plant, again focusing on the heating, cooling and ventilation equipment. We’re going to make a broad assumption that for each system there are 10 inputs we need to focus on.

Calculation 7: Mechanical Plant = 3 systems x 10 inputs = 30 numbers

Ok, our model is basically set up, let’s click “Simulate” and go get a coffee.

Oh you thought we were finished?! Nope, running the model is only part of the process, now we have to extract results and quality check (stay posted for a future blog entry on this!)

When this modeller extracts results, she typically does it on an hourly basis, so that demand costs can be calculated and hourly profiles can be reviewed to make sure that they make sense. Usually there are about 30 variables to look at on an hourly basis (things like: lighting in suites, lighting in common areas, fan power, elevator power, etc.)

Calculation 8: Extract Results = 30 hourly numbers

That brings us to costs. On most residential buildings there are natural gas rates (comprised of 4 types of sub-rates and fees), suite electricity rates (again comprised of 3 sub-rates), and common rates and demand rates (also made of 3 sub-rates).

Calculation 9: Costs = 4 NG sub-rates + 3 electricity x 3 sub-rates = 13 numbers

Let’s check our total so far.

Just over 1,000 numbers, and oh we haven’t built our baseline model yet. Let’s double anything that’s relevant.

Calculation 11: Baseline & Proposed Models = 1676 + 174 hourly = 1850 numbers

And finally, we kept the hourly values separate because they are really a series of numbers for each hour of the year (8760 total). While each individual value likely doesn’t have an enormous impact on the final model, a wrong number would still impact the results. So let’s multiply that out.

Calculation 10: Hourly Numbers = 1676 + (174 x 8760) = 1,525,916

1.5 million values to get right! That’s a bit of an exaggeration since many of those inputs would come from standardized files, but it gives you an idea of how much is going on behind the scenes of an energy model (and how much could potentially go wrong).

So what is the point here?

Well, even if we just count the hourly values once, the total number of numbers we need to input is 1676 + 174 = 1850.

Clarification: that’s the total number of correct numbers we need to input.

And a big part of getting a model right is assigning the values to the right places.

Summing it all up: 1850 numbers in an energy model! (Or 1.5 million)

It makes you wonder how we ever get things right, and yet we do! This happens through a detailed series of reviews and checks that experienced modellers will use on their work.

In addition, we have a good idea of what the results “should” look like. And if they don’t turn out as anticipated, we know where to look to see if the model inputs match the assumptions.

So we’ll end on a high note: you don’t have to know all of those numbers, because your experienced modeller will know them for you!

The good news: Experienced modellers know Which numbers to use

Notes for the engineers:

Ok, we know that this was a back-of-the-napkin kind of post. Things we didn’t account for (and even this list is just an example) include:

- Lots of rooms- rarely do we get a model where all zones are rectangular, and many are much larger than 120 zones

- Lighting controls- these can be complex calculation

- Daylighting- same as above

- Lots of details within the mechanical system… you get the picture!

Post By: Susan Hayes

Interested in more posts on the world of energy performance and modelling in the building industry? Check out our blog at http://www.focaleng.com/blog, or follow us on LinkedIn and Twitter for monthly posts.